01 / Case Study

College of Policing - Merseyside Police

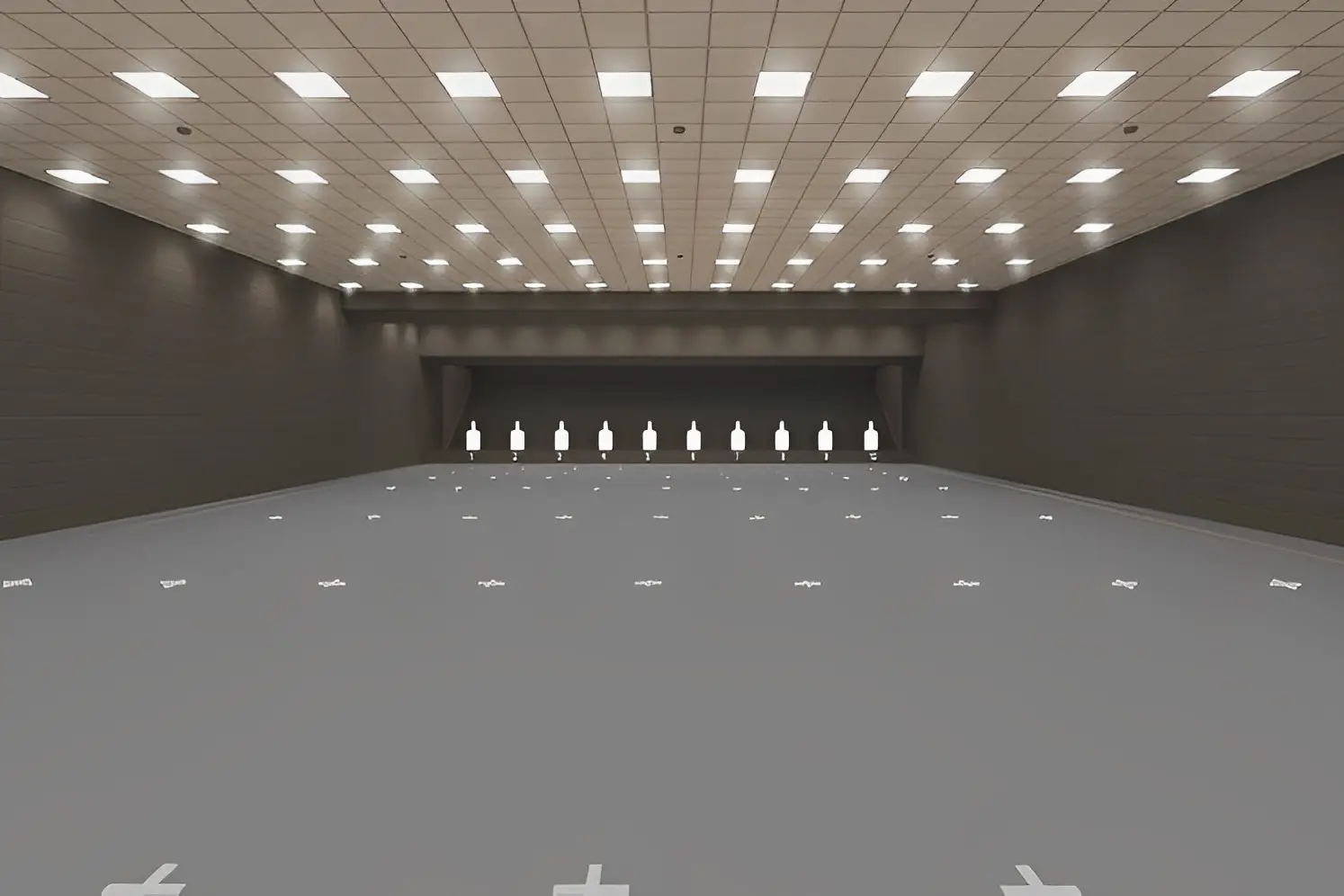

Merseyside Police Training Facility new build on a green field site next to Speke airport comprising a 100 metre firing range an integral accommodation block and an external tactical training area with rope access training.

Location / Merseyside, Liverpool

Contract Value / N/A

Architect / Blue Sky Design Services Limited

Client / Merseyside Police

Completion / N/A

02 / Overview

Overview of the College of Policing - Merseyside Police project

DSSR was responsible for designing and ensuring a steady and uniform air flow in the conversion and refurbishment of a 5,500 metre squared business center into an office and meeting room accommodation, with additional specialist areas such as a museum, an English-style pub, and staff facilities.

The ideal air flow for firing ranges should be laminar, with a negative pressure down range, achieved by an extraction system rated at least 10% higher than the inlet. DSSR considered various options for achieving this flow, including full cross-sectional laminar wall grills, positional grills, and directional vents, depending on firing positions. The air handling system needed to be regularly inspected and maintained, and should handle dust and unburnt propellant safely.

Steady and uniform airflow

Achieving a steady and uniform air flow in firing ranges is crucial for ensuring the safety and comfort of shooters. The ideal airflow should be laminar, with a negative pressure down range created by an extraction system rated at least 10% higher than the inlet.

For a single firing point, the best design involves bringing air through a full cross-sectional laminar wall grill, but this can be costly due to the large volumes of air that need to be heated. Positional grills and directional vents may provide an alternative solution for firing from different positions.

Complex solutions

During trials, it was observed that higher air speeds over the firing point result in increased turbulence in the breathing zone. Optimum air speeds to minimize turbulence are between 0.15 – 0.2m/s, while speeds of 0.1m/s or less do not provide sufficient fresh air, and speeds above 0.3m/s may require heating. The HSE recommends air speeds of not less than 0.25m/s downrange.

In ranges with multiple firing points, the airflow may need to be increased at the rear of the range to ensure adequate airflow overall firing points down range. Complex solutions should only be considered for heavily used ranges, while simpler solutions, such as a single or multiple input and extract fan, are sufficient for low-use ranges. Regular inspection and maintenance of the air handling system is necessary, especially for systems with air handling plant, ductwork, and filters.

Air extraction system

In firing ranges, local airflow and dilution are more important than the number of air changes per hour. Air change rates of between 6-10 changes/hr are generally sufficient for adequate dilution. The air extraction system should provide an extraction rate at least 10% higher than the air input, and handle dust and unburnt propellant safely. Regular switching on and off of the system is necessary to ensure optimum capacity and removal of residual dust after firing ceases.